Reviving Local Grains to Address Climate Change: The Sustainable Organic Soybean Initiative in Guangfu Township

25.11.2025

SUBMITTING ORGANIZATION

Tse-Xin Organic Agriculture Foundation

OTHER CONTRIBUTING ORGANIZATIONS

DATE OF SUBMISSION

REGION

COUNTRY

KEYWORDS

AUTHORS

Jing-Juan Hsu, Tse-Xin Organic Agriculture Foundation

Yu-Chuan Chien, Tse-Xin Organic Agriculture Foundation

Summary Sheet

The summary sheet for this case study is available here.

Abstract

This case documents the rehabilitation of organic soybean in eastern Taiwan and the rebuilding of the industrial chain. Soybean was an important economic crop in Taiwan, with the area under cultivation reaching nearly 60,000 hectares. Later, due to the impact of cheap imported soybeans, the area of local soybean cultivation decreased year by year.

After 2012, the Agriculture and Food Agency (AFA) put forward a policy to promote the rehabilitation of miscellaneous grains, and only then did the area of cultivation increase year by year. Guangfu Township is located in the middle of the eastern part of Hualien County, Taiwan. It is a long and narrow strip of plains, 60% of which is mountainous and the other 40% alluvial. This is also the largest area of soybean cultivation in Hualien County, accounting for almost half of the county’s area. From 2019 to 2022, with the support of the National Development Commission, the project team, together with local farmers and indigenous people, actively promoted the cultivation of organic soybean; adopted friendly measures for the endemic bird Ring-necked Pheasant . The project team have actively cooperated with processors and organic chain channels to create a value chain in the market and support the sustainable management of SEPLs. Over the past five years, with the support of market-based mechanisms, the area of organic soybean planting in Guangfu Township has expanded from 10 hectares to 100 hectares, contributing to Taiwan’s food security and the sustainability of SEPLs in the face of climate change.

1. Introduction

Global climate change has led to food insecurity in recent years. Last year, Brazil, the major food exporter of grains, suffered its worst drought in 70 years, leading to price increases of crops. Trade wars between China and the United States have added to the uncertainty of the global food trade. The year 2025 will likely set a record as the warmest year in recorded history according to the European Space Agency. Heat waves have had widespread effects on crop yields, with notable impacts on maize, rice, soybeans, and wheat in China. (John B & Dawit M 2025)Food security and self-sufficiency in all regions have become important issues for SEPLS management.

Soybean cultivation has been recorded in Taiwan since the early 19th century, and after the 1950s, soybeans became an important economic crop in Taiwan, with the area under cultivation reaching nearly 60,000 hectares. Soy is closely linked to the eating habits of the Taiwanese. Soy-based products such as soya milk, tofu and soy sauce surround the daily local diet.

Taiwan joined the World Trade Organization (WTO) in 2001. The industry has been hit by cheap soybean imports. And the area under local soybean cultivation has been decreasing year by year. (Liaw, Lai and Chen2023) The Agriculture and Food Agency’s website (2025) shows that since 1997, the area under soya beans has decreased from 1,982 hectares to 55 hectares in 2011, which represents a significant reduction in production. In 2014, Taiwan’s soybean self-sufficiency rate was only 0.5 per thousand. (Wu, Lin and Chan 2022)

After 2012, the Agriculture and Food Agency (AFA) put forward a policy to promote the rehabilitation of miscellaneous grains. The AFA has introduced a series of subsidies to encourage farmers to resume growing soybeans, corn and other strategic crops with import substitution or export potential on fallow land. Depending on the type of crop, farmers received between NT$35,000 and NT$70,000 per hectare of land as an incentive to increase domestic food supply. In 2016, AFA also launched the “Great Grain Warehouse Project” to adjust the agricultural structure of the overproducing rice industry. (Agriculture and Food Agency 2025)

The project aimed to establish a production and marketing system for soybean by integrating rice farmers to switch to mixed grains, establishing a group production area and a post-harvest processing center, developing diversified products and marketing to increase the self-sufficiency rate of miscellaneous grains. Only then did the area of cultivation increase year by year. Guangfu Township, the site of this case is located in Hualien County in eastern Taiwan, and is also a major soybean restoration town, accounting for half of Hualien’s soybean production.

It is recognized that grain recultivation is essential for climate adaptation and food security. Organic or environmentally friendly farming practices are more conducive to the sustainable management and ecological balance of SEPLS. This case documented the efforts, challenges and benefits of managing SEPLS to improve the sustainable production of local soybean.

2. Method

2.1.Study Site

Guangfu Township is located in the central part of the Hualien East Rift Valley, Hualien County, eastern Taiwan ,with a long and narrow plain of which 60% is mountainous and the other 40% is an alluvial plain formed by rivers. There are the Central Mountain Range to the west and the Coastal Mountain Range to the east, and Fata’an Creek, Hualien Creek and Guangfu Creek flow through the township. Guangfu Township has a population of about 11,000, of which more than 9,000 are farmers. Guangfu is also the largest and most concentrated soybean production area in Hualien County, owning 1/2 of the soybean planting area in Hualien County.

2.2 SEPLS of the Area

Guangfu Township is an agricultural township with a cultivated area of about 5,000 hectares (about 30% paddy fields and 70% dry fields) and a population of about 11,000, of which about 9,050 are farmers. During the Japanese colonial Period and after the Second World War, there were sugar factories in the area, and because of the flat terrain and fertile soil, sugarcane, the raw material for sugar production, was the main crop. Later, due to international trade pressures and rising costs of Taiwanese sugar industry, the sugar factory was closed in 2002 and Guangfu Sugar Factory was transformed into a tourism spot At present, the main agricultural products of Guangfu township are rice, bamboo shoots, fruit trees, glutinous red rice and betel nuts.(Guangfu Township Office 2025)

According to statistics from the Agriculture and Food Agency, the production area and volume of soybeans in Hualien County did not exceed 100 hectares from 2010 to 2016, and with the implementation of the Great Grain Warehouse Project in 2016, the total production area of soybeans in Hualien County exceeded 250 hectares in 2017, an increase of 1.5 times, with production accounting for about 8% of the national total, but the increase in production from 2017 to 2019 is not significant. Among them, Guangfu is the township with the highest soybean production in the county, accounting for more than half. (Agriculture and Food Agency 2025)

Guangfu township is also the habitat of the ring-necked pheasant, a grade 2 protected animal. Grassy areas such as soybean fields, especially organic soybean fields that do not use herbicides, are particularly suitable for the survival of ring-necked pheasants. Therefore, the fields have both productive and ecological multifunctional functions, and if the area of organic soya bean fields is expanded, it will bring both productive and ecological benefits to the SEPLS.

2.3. Project Operation

From 2019, with the support of the National Development Commission, the project team from Tse-Xin Organic Agriculture Foundation(TOAF), together with local farmers and indigenous people, actively promoted the cultivation of organic soybean adopted friendly measures for the endemic bird Ring-necked Pheasant.

At the beginning of the project team’s entry into Guangfu Township, organic farmers were working alone, and there was no organisation that aimed to promote friendly soybean cultivation here. Because of the lack of stable sales channels, farmers are afraid to expand the area; although there are small processors who come to buy, their purchases are very small and unstable, so it is impossible to develop large-scale cultivation, and the whole organic soybean planting area in Guangfu Township is only about 10 hectares.

2.3.1 Establishment of Co-operative Production Organizations–Hualien Soya

Soybeans are drought resistant and may have an advantage in adapting to drought conditions, but farmers are unable to adopt sloppy farming to increase or maintain production Post-harvest operations include drying, saturation grading, grain size grading, color selection and storage facilities. Because individual farmers grow on a small scale, it is difficult for them to invest in machinery and equipment, and the high demand for labor makes the scale of cultivation very limited.

Therefore, the project team, TOAF, together with the farmers, set up a production co-operative organization using “Hualien Soya” as a common brand and invited more farmers to join to form a production alliance. In the process of soybean sowing, weeding and harvesting, the alliance plays the role of a platform for sharing working machinery and mutual assistance in farming, sharing post-harvest drying and sorting equipment, and joining the soybean industry supply chain to provide raw materials to processing plants.

The Hualien Soya Alliance also provides a platform for farmers to share and learn about soy cultivation techniques. The project team has worked with experts to address various technical issues in soybean production, including soil management, prevention and control of red fire ants, rhizobia inoculation trials and the introduction of drones to help farmers improve their soybean production techniques and quality.

2.3.2 Development of Processed Food

To support the sustainable management of SEPLS through a sustainable soybean industry, the development of distinctive local soybean processed products is one of the most important means to create the sustainable value chain. The processing and marketing aspects of value addition in SEPLs are more challenging than the challenges of stabilizing crop yields and quality. Hualien soybean industry, it is inevitable that crop quality and yield are unstable due to physical, chemical, biological and other environmental factors in the production area. Quality and yield are the basic conditions for considering the interface with the processing end and the market end after harvest. How to meet the crop specifications and quantities that are acceptable to the processing end is the main focus of the project team’s support.

With the help of sales channel ,the project team actively visited various food processing plants and discussed with more than 15 processing plants the possibility of product development for soybeans. Raw material preparation, flavor design and proofing, manufacturing process and market evaluation are all involved in developing food products. At the same time, we have also matched the processing industry with production site visits, inviting manufacturers to visit soybean fields to learn about soybean production and the selection of post-harvest and drying operations. We discussed the specifications of the soybeans used in various soy products (e.g. miso).The development of each new processed product is a costly endeavor for processors, requiring additional time for sampling and testing.

2.3.3 Co-operation with channels for stable sales

In the process of building a sustainable local soy value chain, marketing presents the biggest challenge—how to sell the products. Soy is a staple food in Taiwan, but due to the high cost of raw materials, there are few local organic soy products available in the market. However, from the perspective of developing a niche market, local soybeans offer significant advantages. Unlike imported soybeans, which are transported over long distances, local soybeans are fresh, seasonal, and have the shortest food mileage, making them a preferred agricultural product that is nutritious, environmentally friendly, and safe. There remains great potential for the development of domestic organic soybeans.

Retail channels, with their market access and deep understanding of consumer characteristics, are skilled at estimating costs and profits. However, the social landscape has evolved rapidly in recent years, and for retail channels, the ability to differentiate products and target specific customer segments is crucial for survival in a changing market. If these channels can proactively develop processed soy products and partner with upstream processing plants to source specific local raw materials, they will not only provide consumers with safe and delicious products but also create a distinctive brand identity. This strategy will drive sales and add value to SEPL’s sustainable value chain, ultimately enhancing economies of scale.

The project team has organized numerous meetings between distributors and producers, bringing together physical channels, online shops, and group buying initiators to connect with producers. These meetings help distributors gain a deeper understanding of the producers and product characteristics, linking the end market with the production process and allowing distributors to appreciate the benefits of sourcing locally.

Channels chose the processing factories they wish to work with, and the raw materials were labelled to indicate the use of Hualien soybeans, and the “Hualien Soya” logo was displayed on the product packaging, thus creating the branding benefits of “Hualien soya”.

3. Results

3.1 Growth of Hualien Soya

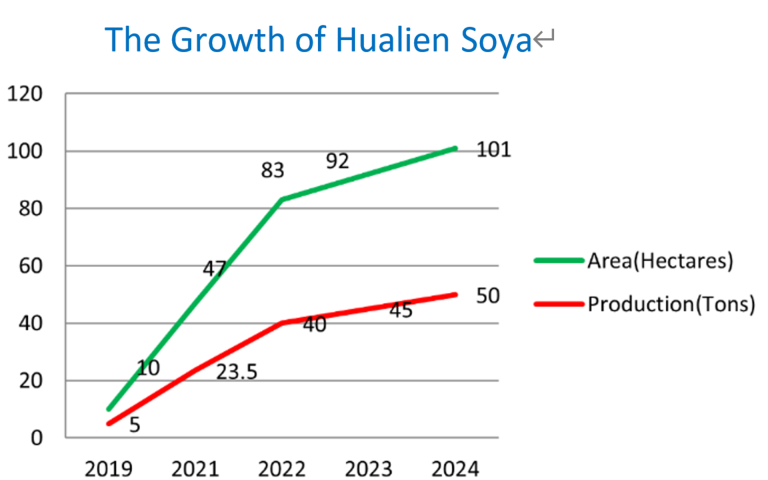

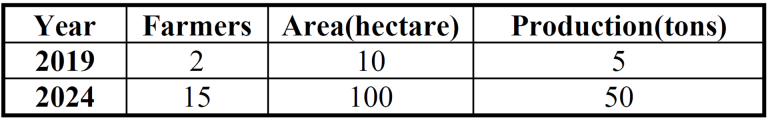

Over the past five years from 2019-2024, with the support of market-based mechanisms, the area of organic soybean cultivation under the co-brand Hualien Soya has expanded from 10 hectares in 2019 to 100 hectares in 2024 with more than 15 farmers, contributing to Taiwan’s food security and the sustainability of SEPLs in the face of climate change.

Soybean farmers are confident in expanding their farmland because they have a stable sales channel for their raw materials. This confidence has led them to invest in machinery and equipment, ensuring a consistent supply of raw materials to processing plants and distribution channels. These investments also improve the efficiency of soybean sorting and grading, resulting in stable product quality and better sales performance across channels. This positive cycle helps sustain the production of high-quality soybean raw materials.

The “Hualien Soya” Alliance has made significant investments in soybean industry machinery and equipment, not only for its own production but also to support small farmers at towns nearby. These services include field ploughing, soybean harvesting, and transportation to the Guangfu drying, sorting, and packaging facilities. As a result, Guangfu has become a key hub for organic soya farming and post-harvest processing in Hualien. The Alliance’s services also support small farmers lacking the necessary machinery and equipment, providing them with essential tools. Hualien’s good bean farmers can also receive income from providing farming services, which helps to reduce the pressure of purchasing farm equipment loans.

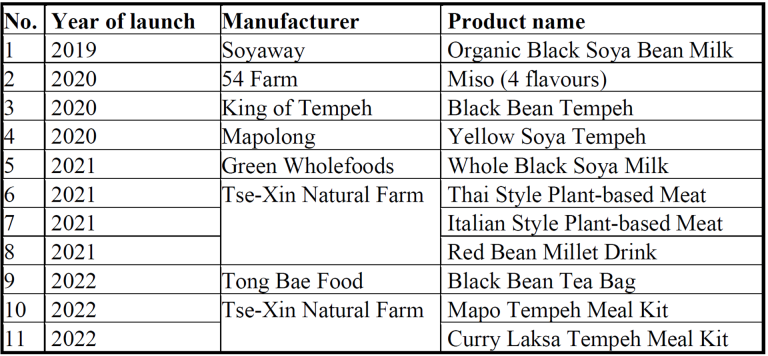

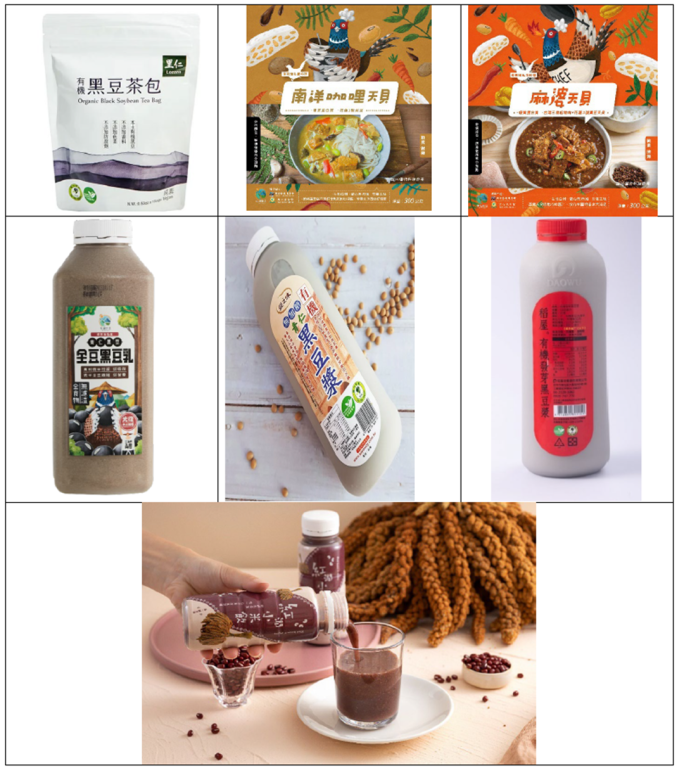

3.2 Product Developed

Since 2019, the project team has developed and launched over 10 processed bean products, successfully supporting Hualien Beans members to steadily grow local organic beans and increase production under fixed contracts with food processors from 12 tonnes in 2020 to 46 tonnes in 2024.

By the end of 2022, the National Development Commission stopped providing subsidies. However, “Hualien Soya” has successfully established a sustainable business model and continues to develop products such as soy sauce, sprouted black soy milk, and plant-based protein essence. Since 2024, with the support of the Hualien County Government, “Hualien Soya” has supplied raw materials to produce organic soy milk, which has now become part of the free school meal program. These efforts helped sustain and grow the sustainable value chain of local SEPLs!”

3.3 Product Selling

The project team has been continuing to develop a variety of processed products and sell them through multiple channels. Since the products achieved excellent sales results, the channels are willing to continue selling the products and at the same time support the local organic raw materials in Huadong. From 2019 to the end of 2021, the sales volume of related products exceeded $ NTD 23 millions. Although no further records have been kept since then, it can be deduced that the increase in sales revenue is inevitable due to the continuous increase of products.

4.Disscuion and Lesson Learned

4.1 Importance of Co-operative Organization

Agriculture is a highly localized and specialized industry. Cooperative organizations such as Hualien Soya, by jointly developing economies of scale, investing in machinery and equipment, and providing contract farming services to each other, have to some extent alleviated the labor problem and broken the hard work of individual farmers who have to struggle alone in the process of planting, product development and sales, and have also expanded the niche of sustainable agriculture through mutual cooperation, thus expanding the sustainable value chain of SEPLs.

4.2 Complexity of developing products

For farmers one of the ways to add value to the sustainability of SEPLS is developing processed foods. But it is a complex and multifaceted process. It involves identifying the target customer, determining the type of product, selecting the right manufacturer, investing in development costs, establishing distribution channels, designing packaging, and managing inventory—all of which require careful consideration. For processing factories, challenges arise when a commodity is out of stock due to insufficient agricultural supply, leading to instability in production. This situation can result in financial losses and may prompt factories to seek alternative raw materials, which in turn affects sourcing relationships and negatively impacts plantation areas.

Food processing factories operate under a concept known as “MOQ” (Minimum Order Quantity), which refers to the minimum quantity of goods required for production. This is because factories need to set up specialized production lines for each customer, and once a production line is activated, a certain volume of goods must be produced. While larger MOQs can reduce the average cost per unit, they also increase storage costs and sales pressure. On the other hand, smaller MOQs tend to result in higher per-unit costs but alleviate storage pressures. The MOQ is a key consideration when selecting a suitable processing plant.

4.3 Necessity of Alternative Selling Model

When farmers develop and sell their own products, they must manage various tasks such as marketing, pricing, storage, and shipping—areas in which they may not have expertise. As a result, in this case study, it is often necessary to find a partner who can support sales through distribution channels or directly collaborate with these channels to involve the original food processing plant in product development. This strategy ensures that the developed product has a clear sales path once completed, preventing the issue of unsold products after development.

However, the profitability of farmers’ sales of processed products through these channels is often lower than their direct sales to consumers. To address this challenge, we are developing an alternative cooperation model for this project. In this model, the project team takes responsibility for research and development of the processed products, purchasing raw materials from farmers in Hualien Soya. The team then finds suitable processing factories to produce the products using specified raw materials, pays for the OEM fees, manages the warehouse, and handles market development and sales. The farmers can buy back the finished products at a wholesale price and sell them.

In this model, farmers are relieved from the burdens of developing products, finding suitable processing plants, and covering development costs. They don’t have to bear the production costs for OEM or the pressure of managing inventory. However, they can still benefit by being able to sell the processed goods and receive profits from those sales. Such a model allows for more direct support for the livelihoods of local communities and the farmers.

5.Conclusion

Global climate change is causing instability in the international food supply, but it is also creating opportunities for local food systems to recover. By integrating organic farmers, processors, and channels, this case has successfully increased the acreage of local soybeans in eastern Taiwan, positively contributing to the conservation the habitats of ring-necked pheasant and building the sustainability of local SEPLS. This case documents the rehabilitation of organic soybean in eastern Taiwan and the rebuilding of the industrial chain. We summarised effective ways and success factors of integrating multiple stakeholders, including farmers, processors and retailers, to promote a more sustainable, equitable and climate-resilient local organic industry.

Acknowledgements

The project acknowledges the support from the National Development Commision for providing the funding for the implementation of the project. Thanks to our partners, Hualien Soya Agricultural Marketing Co-operative Society, Yizhu Grain Production Co-operative Society, Hualien County, for showing your passion to soya recultivation. We extend our thanks to Leezen Company LTD, Soyaway CO., LTD, Greene’s Whole Foods Co, Ruhn Chan International CO., LTD, Swanheart CO., LTD, Tse-Xin Natural Organic farm Corporation, Min Ji Tofu CO., LTD, Daowu Natural Foods Co., Ltd, Tong Bae Food CO., LTD, Chun Chiao Food Industries CO.,LTD, Goldencrops Corporation, Taiwanway Social Enterprise Corporation., Chen Yuan Ho Soy Sauce Factory, Feng Rong District Farmers’ Association, Xie Li Product CO., LTD, Shian Yong Kitchen Co.,Ltd for developing the processed product. We are also grateful to the Hualien District Agricultural Research and Extension Station for its agricultural technology support, and to the Agriculture and Food Administration for its grants for agricultural machinery and equipment.

References

References

John B,Dawit M (2025) Risks and challenges in global agricultural markets, The World Bank Blog, Viewed 31 March 2025 <https://blogs.worldbank.org/en/developmenttalk/risks-and-challenges-in-global-agricultural-markets>

Liaw IL, Lai HY, Chen YJ, Shy JY (2023) Food Security in an Era of Inflation: The Importance of Maintaining Good Seeds. Harvest 73 (7):10-14

Wu JH, Lin JS, Chan KJ (2022) The Search for Soya Beans: The Evolution of National Soya Beans. Harvest 72 (10):32-37

The Agriculture and Food Agency 2025 , The Agriculture and Food Agency ,Taipei, Viewed 28 March 2025 <https://agr.afa.gov.tw/afa/afa_frame.jsp>

Agriculture and Food Agency 2025 , The Agriculture and Food Agency Viewed 31 March 2025 <https://www.afa.gov.tw/cht/index.php?code=list&ids=286>

Guangfu Township Office 2025 , Industry Overview Viewed 31 March 2025 <https://www.guangfu.gov.tw/cp.aspx?n=1223>